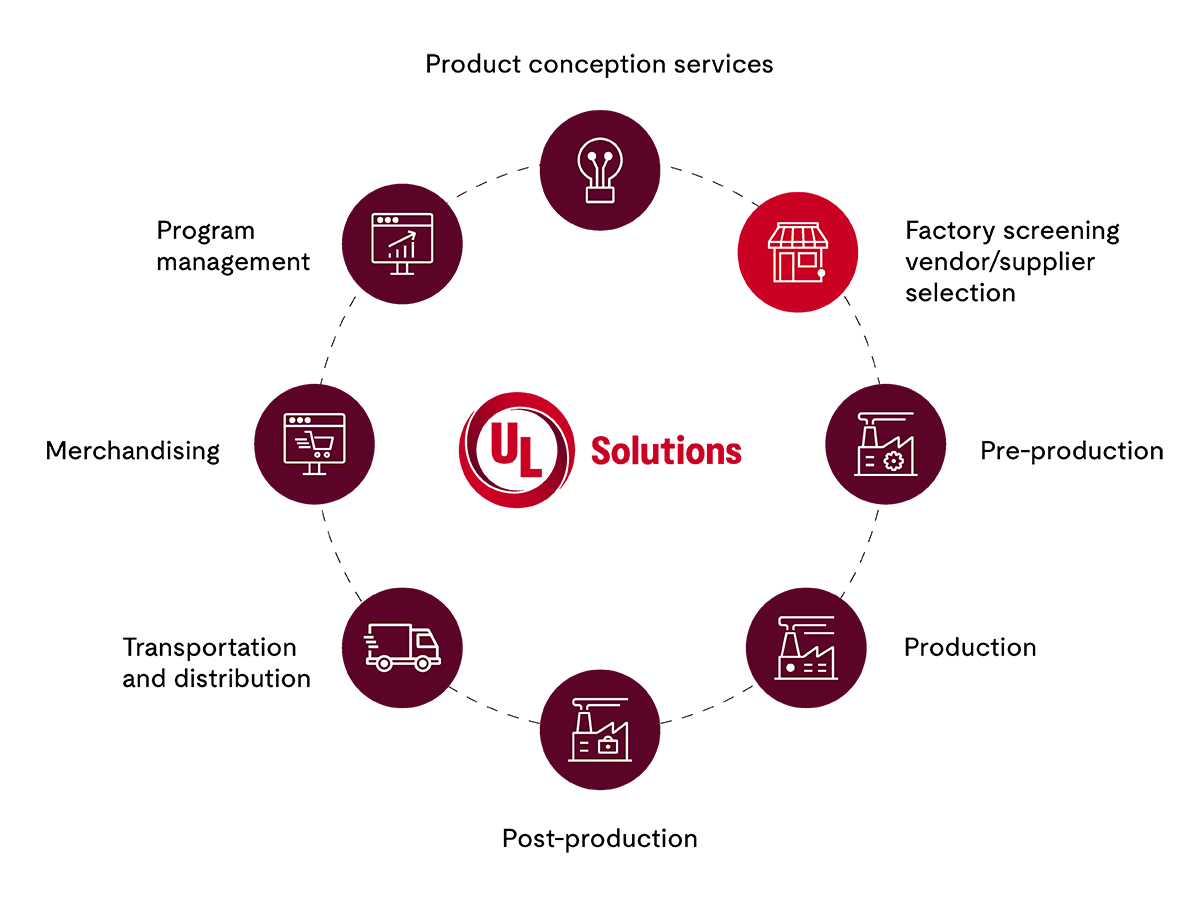

Third-party inspection services to assess compliance to safety and quality requirements

Third-party inspections of consumer goods provide a key checkpoint in a global quality assurance program. They help evaluate whether that product meets specifications and requirements prior to release and shipment.

UL Solutions maintains a team of trained inspectors across all categories of consumer goods, located in major sourcing regions, to support customer programs. We also operate global systems for training, quality and integrity across our inspections team.

We play a key role in supporting major global retailers in designing and customizing global inspection programs to meet their specific requirements. Our global reach, expertise and data management systems help reduce the risk of substandard products being shipped.

UL Solutions provides various types of inspections for consumer goods

Factory screening

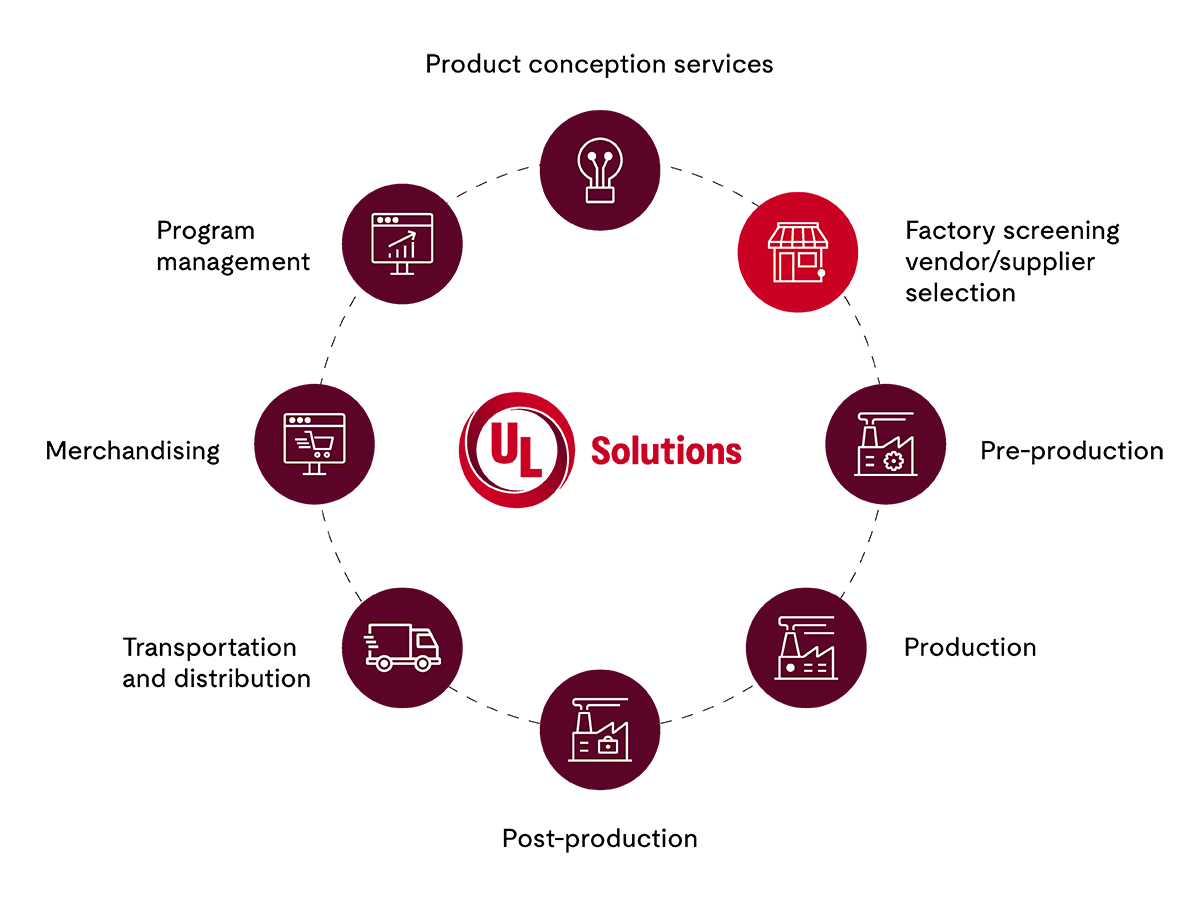

Today’s market dynamic is fast-paced, and many companies in the retail sector are proactively adjusting supplier and sourcing strategies to optimize production processes. With inspectors based in established and emerging sourcing areas, UL Solutions can help assess factory capabilities and readiness, conduct training aligned with your expectations, audit quality requirements and monitor production from start to finish.

Our factory screening services help identify potential areas of concern at new manufacturing facilities before production begins.

Factory screening is a quick deployment assessment that provides retailers and brands with basic information and data points about a new potential manufacturer.

This non-scored assessment covers the following areas:

- Business licenses

- Quality management systems

- Incoming raw materials control

- Production controls

- Finishing, packaging and storage controls

- Contamination control

- Health and safety

- Child or forced labor

Top of production inspections

Top of production (TOP) inspections are performed on raw materials and first-run products. Before full production begins, UL Solutions inspection teams evaluate the first 200 units to assess compliance with necessary criteria, including regulatory requirements and brand specifications.

During production inspections

During production (DUPRO) inspections help identify and address issues in the manufacturing process before the order is completed, helping to minimize risks of delays to the shipping schedule. UL Solutions conducts product inspections once a minimum of 20% — but no more than 40% — of finished goods are produced to support quality throughout the manufacturing process.

Pre-shipment inspections

Pre-shipment (PSI) inspections serve as a final check to evaluate product quality, packaging, product labeling and carton markings, confirming that items are correctly packed and suitable for their intended use. The PSI is conducted at the 100% production mark, with at least 80% of goods packed and placed in shipping cartons for verification against your purchase specifications.

Loading inspections

Loading inspections are conducted at the factory or port to verify quantities, confirm loading and seal the container. These inspections also check that the products have not been tampered with. Production schedules should be shared in advance so UL Solutions can coordinate with the factory to plan loading inspections.

UL Solutions offers additional consumer product inspection services designed to support your specific goals

Quality assurance platform

Our Performance Analysis and Trending Hub (PATH) is a single platform for all quality assurance data, including inspection, testing and audit results. This online tool uses data analytics to predict potential quality problems that require attention.

Dedicated program management

UL Solutions’ global service delivery approach includes inspector qualification training, supervision of third-party contractors, integrity protocols and quality control systems. Our program management team offers global coverage and expertise across product categories to support efficient service delivery.

Why trust UL Solutions for consumer product inspections?

UL Solutions inspection services for consumer products offer quality, expertise and innovation.

- UL Solutions supports major brands and retailers with customized global inspection program parameters to meet their business requirements, applying best practices and new ideas.

- We deliver specialized product category knowledge, responsive service and a data-driven approach to help meet quality goals.

- Our teams provide training, oversight, governance and data analysis for Supplier Self-Inspection programs and help investigate and address the root causes of nonconformances through engineering and training services.

Let us know how we can support your quality goals.

In the News - Regulatory Updates for Retail and Consumer Products

Consumer product regulations are evolving rapidly. Subscribe now and start receiving this monthly newsletter to stay on top of regulatory changes for your business and navigate compliance challenges.

Get connected with our sales team

Thanks for your interest in our products and services. Let's collect some information so we can connect you with the right person.