Automotive SPICE® is an established framework model in control unit development that enables companies to evaluate and improve their processes. The automotive industry-specific standard was developed in 2005 by the VDA’s Quality Management Center, with the involvement of experts from UL Solutions. The model, currently in its fourth generation, is also used in other sectors, such as in the development of construction machinery, tools and refrigerators. Automotive SPICE® is a trademark of VDA QMC.

Leading vehicle manufacturers have chosen Automotive SPICE ® as the binding standard for their suppliers’ processes. The model consists of a structured collection of best practices from the car manufacturing industry and includes industry-specific models for the development of systems, software, hardware and machine learning.

Automotive SPICE® supports suppliers in improving the quality of their systems, establishing processes, meeting deadlines and managing customers’ requests for changes while managing systems’ increasing complexity.

Systems development in the VDA Scope

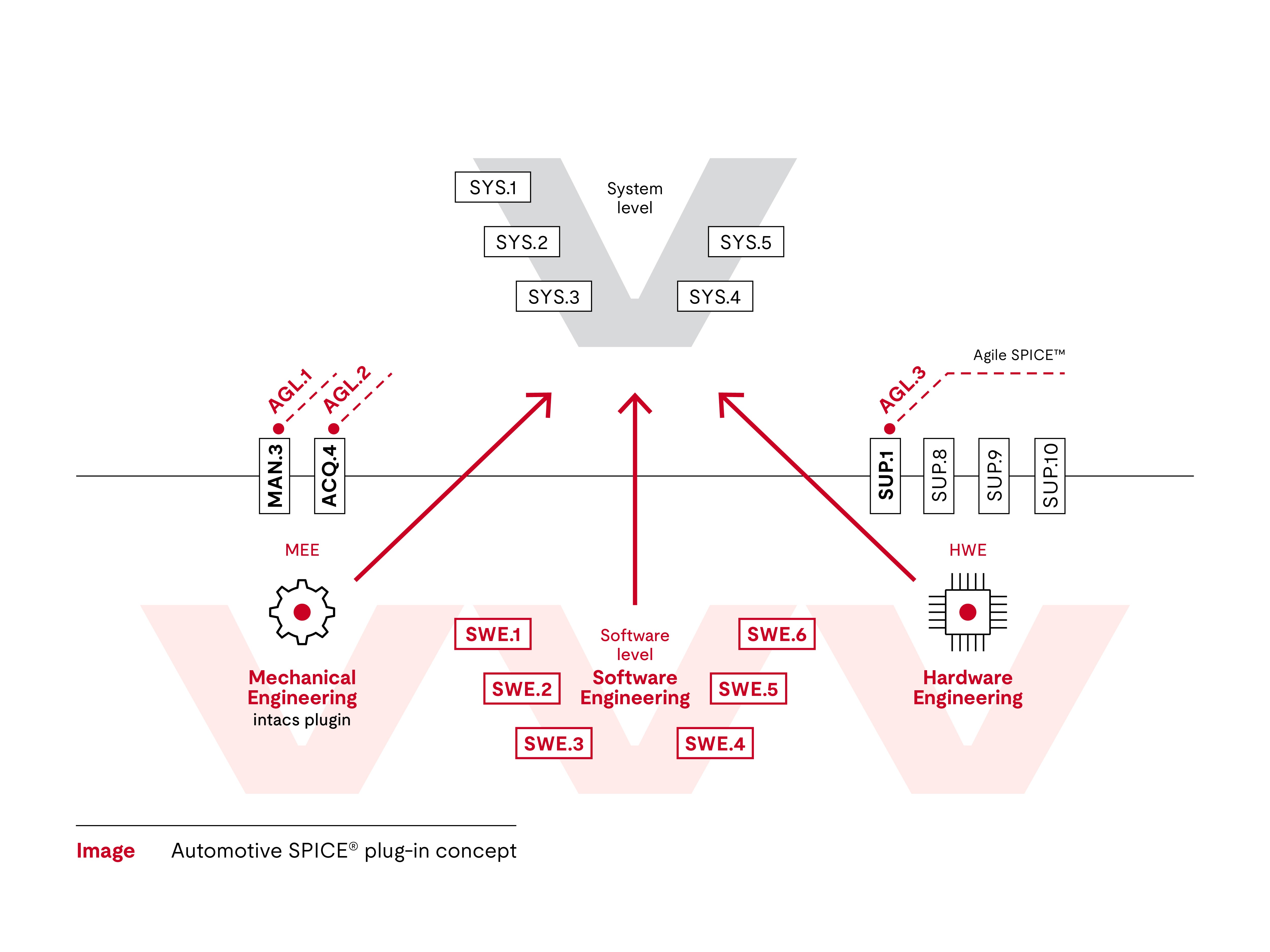

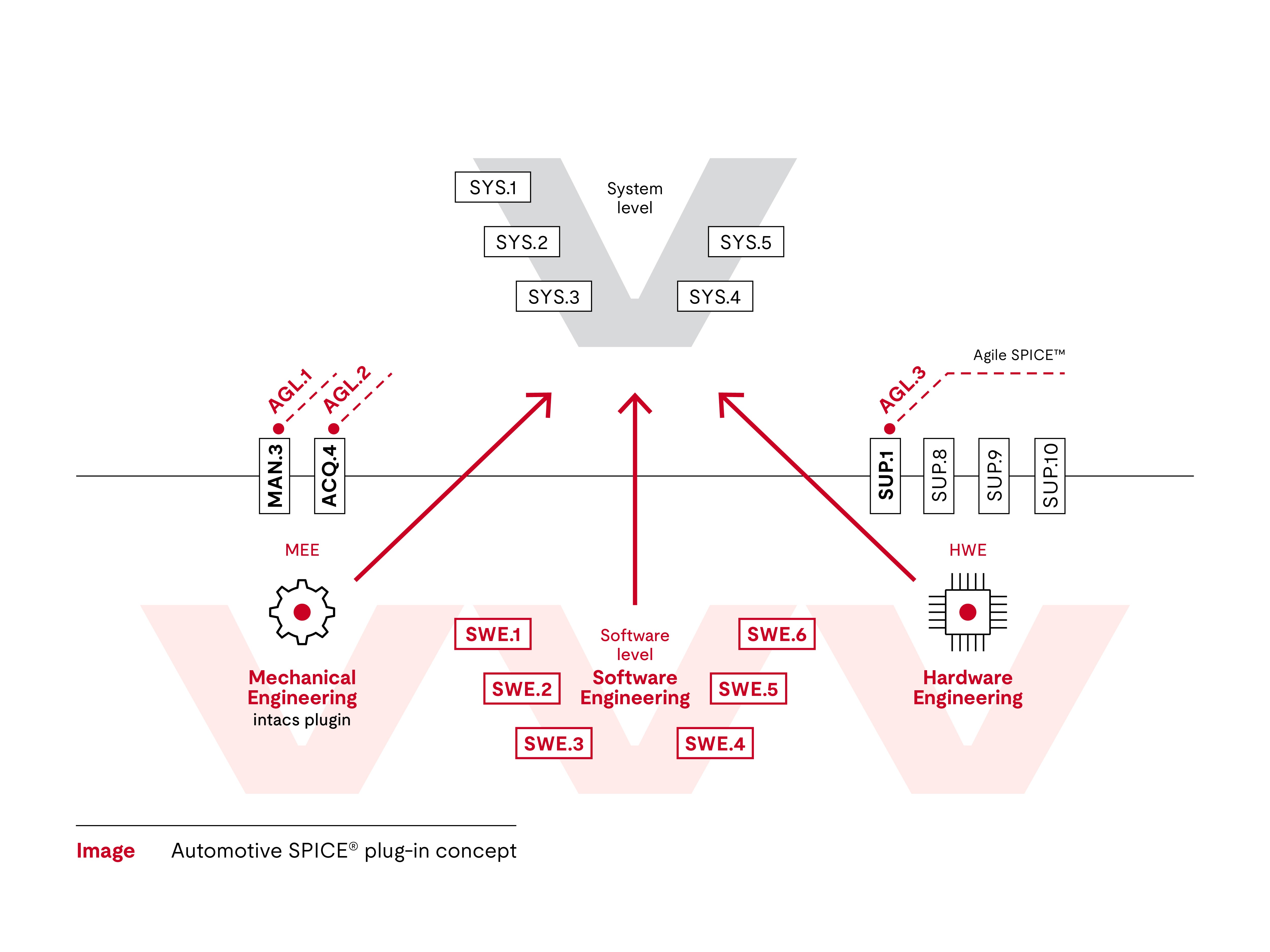

The German Association of the Automotive Industry (VDA) has identified a VDA Scope comprising a basic part that encompasses management and supporting processes and a set of domain-specific parts that covers systems engineering, software engineering, hardware engineering and machine learning. In addition, a set of processes in the Flex Scope, an extension within the Automotive SPICE® framework, can adapt to the specific situation of a given project.

To leverage the benefits of Automotive SPICE® in the development of mechatronics systems, it is designed as a plug-in model. Development processes for other engineering disciplines can be added.

Basic part

- Management

- MAN.3, Project Managment

- Support

- SUP.1, Quality Assurance

- SUP.8, Configuration Managment

- SUP.9, Problem Resolution Management

- SUP.10, Change Request Management

Domain-specific part

- Systems engineering

- SYS.1, Requirements Elicitation

- SYS.2, System Requirements Analysis

- SYS.3, System Architectural Design

- SYS.4, System Integration and Integration Verification

- SYS.5, System Verification

- Software engineering

- SWE.1, Software Requirements Analysis

- SWE.2, Software Architectural Design

- SWE.3, Software Detailed Design and Unit Construction

- SWE.4, Software Unit Verification

- SWE.5, Software Component Verification and Integration Verification

- SWE.6, Software Verification

- Hardware engineering

- HWE.1, Hardware Requirements Analysis

- HWE.2, Hardware Design

- HWE.3, Verification Against Hardware Design

- Hardware design

- HWE.4, Verification Against Hardware Requirements

- Machine learning engineering

- MLE.1 Machine Learning Requirements Analysis

- MLE.2 Machine Learning Architectures

- MLE. Machine Learning Training

- MLE.4 Machine Learning Model Testing

Process improvements with Automotive SPICE®

The Automotive SPICE® model can be used to evaluate whether a work process is adhered to and incorporated in daily practices. The model uses capability levels 0-5 to denote that a process has been achieved. Level 0 signifies basic, incomplete processes, Level 1 indicates accomplished objectives. Level 2 focuses on managed and dependable work products. Level 3 is an established process within the organization, Level 4 indicates predictable outcomes, Level 5 are processes that are evolving and maturing. To achieve a particular level, the relevant Automotive SPICE® model elements must be implemented in their appropriate form.

Assessments evaluate performance

Numerous car manufacturers use Automotive SPICE® to screen and assess the risk of their suppliers; suppliers must demonstrate a particular maturity level in terms of the relevant processes. Manufacturers ascertain whether or not a company has achieved the required capability level by means of the assessment, which highlights the supplier’s strengths and weaknesses and makes recommendations for improvements. Assessments are only recognized by the VDA if they are carried out by intacs®-certified specialists.

New workflows, processes and changes in corporate culture are often required for an organization to achieve a new capability level. Therefore, improvement measures often take considerable time to implement. In a larger-scale automotive organization, the measures needed to achieve and sustainably maintain level 3 typically take several years to implement.

Automotive SPICE® services from UL Solutions Software Intensive Systems

UL Solutions Software Intensive Systems can support automotive original equipment manufacturers (OEMs) and suppliers in:

- Achieving the required capability levels within key development processes

- Systematically improving existing workflows and methods

- Evaluating the status of process improvements through formal assessments and gap analysis

- Fulfilling the requirements of Automotive SPICE® in harmony with security, functional safety and agile methods

- Training staff and assessors

Get connected with our team

Thanks for your interest in our products and services. Let's collect some information so we can connect you with the right person.