Overview

- Concentric or eccentric knockouts that are part of a cabinet, cutout box, junction box, or pull box, installed in circuits of over 250 volts to ground and that have not been investigated for grounding and bonding, would require a bonding jumper to be installed.

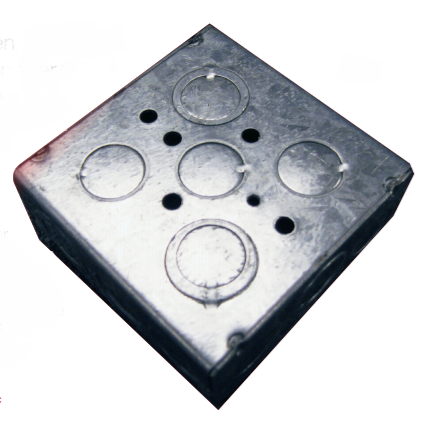

- Metallic outlet boxes that contain concentric or eccentric knockouts covered by UL product category for Metallic Outlet Boxes (QCIT) have been evaluated for grounding and bonding of electrical systems with voltages above and below 250 volts to ground.

- When concentric or eccentric knockouts are encountered with service equipment, a bonding jumper would be required.

- If the integrity of the concentric or eccentric knockouts has been compromised during installation, a bonding jumper should be provided to ensure compliance with all the requirements of the NEC.

Bonding at services

NEC Section 250.92(B) is applicable to bonding at services, and in part states, “Bonding jumpers meeting the requirements of this Article [Article 250] shall be used around impaired connections, such as reducing washers or oversized, concentric, or eccentric knockouts.” For services, this confirms that bonding jumpers are required unless all concentric or eccentric knockouts have been removed.

Bonding for over 250 volts to ground

For bonding circuits over 250 volts to ground, NEC Section 250.97 is applicable, and by exception, allows concentric and eccentric knockouts to be used without bonding jumpers, provided the box or enclosure with concentric or eccentric knockouts is listed to provide a reliable bonding connection. For the UL Solutions product category for Metallic Outlet Boxes (QCIT), UL guide information indicates “All boxes with concentric or eccentric knockouts have been investigated for bonding and are suitable for bonding without any additional bonding means around concentric (or eccentric) knockouts were used in circuits above or below 250 V and may be marked as such.” Please refer to UL Product iQ® and enter “QCIT” into the search box.

Access Product iQ for information on thousands of UL Certified products, components and materials.

Electrical testing of metallic outlet boxes

The applicable requirements for UL certification (listing) of metallic outlet boxes are in UL 514A, Metallic Outlet Boxes. In addition to knockout mechanical secureness testing, each box employing concentric or eccentric knockouts is required to comply with an electrical test, commonly known as a short time current test. For this test, a 6-inch length rigid metal conduit is secured to the smallest concentric or eccentric knockout by 2 locknuts. A test current of 1180 A for 4 seconds (1/2 trade size) or 1530 A for 6 seconds (3/4 and 1 trade sizes) is passed from the conduit to the outlet box. As a result of the application of the current, the outer knockout is required to remain in place, and continuity is required to be maintained between the box and the conduit. Arcing and burning during the test are common and are acceptable.

Other types of metallic enclosures

Cabinets and cutout boxes, in accordance with NEC Article 312, as well as junction and pull boxes, in accordance with NEC Article 314, may also employ concentric or eccentric knockouts, and are evaluated for UL certification (listing) in accordance with UL 50, Enclosures for Electrical Equipment (CYIV and BGUZ). In contrast with metallic outlet boxes, these other types of metallic enclosures with concentric or eccentric knockouts are not required to be subjected to a short time current test. As such, NEC Section 250.97 would require that bonding jumpers be used unless all concentric or eccentric knockouts were removed. For the UL Solutions Guide Information, please refer to UL Product iQ enter “CYIV” or “BGUZ” into the search box.

Additional NEC requirements

When inspecting for proper grounding and bonding of electrical equipment that contains concentric or eccentric knockouts, the AHJ should verify that the integrity of the remaining concentric or eccentric rings has not been compromised during the installation process.

- NEC Sections 250.4(A) & (B) have several provisions that require non–current-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, to be connected together and to the electrical supply source in a manner that establishes an effective ground-fault current path.

- NEC Section 250.90 requires that bonding shall be provided if necessary to ensure electrical continuity and the capacity to conduct safely any fault current likely to be imposed.

- NEC Section 250.96 requires metal raceways, cable trays, cable armor, cable sheath, enclosures, frames, fittings and other metal non–current-carrying parts that are to serve as equipment grounding conductors, with or without the use of wire-type supplementary equipment grounding conductors, to be bonded if necessary to ensure electrical continuity and the capacity to conduct safely any fault current likely to be imposed on them.

In addition to Article 250, Article 300, specifically Section 300.10, requires metal raceways, cable armor, and other metal enclosures for conductors to be metallically joined together into a continuous electrical conductor and to be connected to all boxes, fittings, and cabinets to provide effective electrical continuity.

Connect with us

Resources, support, and expertise to help you when you need it, wherever the job takes you. Join the community today.