Project management is the most critical factor for project success. Often, projects have no clear scope definition; the project effort is severely underestimated. There isn’t enough staff capacity while customer requests for new features rapidly come in.

As a result, customers are mad, and projects became nightmares!

The following are the three most important activities of Project Management in Automotive SPICE®:

- Define the project scope clearly. The project scope describes what the project is about and what it shall accomplish. If you don't have a clear project scope, you don't have a basis to estimate your effort, and then you have no justification for your personnel capacity. Many projects have far too much work for too few people. The result is more firefighting than professional work: constant hurry, poor quality and frustrated staff.

Here is your answer for how to define a realistic project scope: Your inputs are the customer requirements and feature rollout plan, and documents need to be checked for technical feasibility, realistic timing and the question of whether you can cope with the staff build-up quickly enough.

Another input are the development processes of your company that will tell you what internal work you need. Similar projects from your company’s past are a great resource.

In the first step, you develop the Project Scope Statement. This is a high-level definition of the product to be developed, as well as the deliverables at their respective milestones.In the second step, you develop the Work Breakdown Structure (WBS). The WBS describes everything that is delivered to the customer and all necessary internal project work.

- Plan and monitor the work carefully. If you do not follow some simple rules in a disciplined manner, you can invest a lot of energy in planning and monitoring and still not be effective — and potentially derail the project. Here are some suggestions:

- Do not plan in detail for distant periods of time. Use “rolling wave” planning to plan the next development cycle in detail, while distant cycles are superficially planned.

- Do not try to plan tasks with a duration of less than one day at the lowest planning level. Try to have an average duration of about one week.

Workflow management tools allow you to easily track work progress and hours spent compared to planned hours. This is very helpful in identifying tasks that go wrong. Technical meetings usually take place on a weekly basis. Use these meetings to discuss progress, issues, forecasts and outlooks.

-

Manage your stakeholders carefully. I have seen projects that have failed simply because they forgot to involve the right stakeholders.

A project lives and dies with the people involved! There are many studies that show that projects with poor stakeholder management are much more likely to fail. Professional stakeholder management basically works in four steps:

- Identify potential stakeholders. You can perform brainstorming in your team or conduct interviews with stakeholders to identify additional stakeholders.

- Analyze the stakeholders. A very powerful method is the Power/Interest Grid, which offers you a very effective classification of the stakeholders into four categories.

- Plan how to engage stakeholders. You can use a stakeholder engagement grid to plan how to bring a stakeholder from a current engagement level to a desired level.

- Manage and control stakeholder engagement. Communicate and work with stakeholders to bring their engagement to the desired level.

Project Management – the process according to Automotive SPICE®

The purpose of the Project Management Process is to identify, establish and control the activities and resources necessary for a project to produce a product, in the context of the project’s requirements and constraints.

BP1: Define the scope of work. Identify the project's goals, motivation and boundaries.

BP2: Define the life cycle for the project, which is appropriate to the scope, context, magnitude and complexity of the project.

NOTE 1: This typically means that the project life cycle and the customer's development process are consistent with each other.

BP3: Evaluate the feasibility of achieving the goals of the project in terms of technical feasibility within constraints with respect to time, project estimates and available resources.

BP4: Define, monitor and adjust project activities and their dependencies according to defined project life cycle and estimations. Adjust activities and their dependencies as required.

NOTE 2: Adequate progress monitoring can take place when there is a structure and a manageable size of the activities and related work packages.

NOTE 3: Project activities typically cover engineering, management and supporting processes.

BP5: Define, monitor and adjust project estimates of effort and resources based on project's goals, project risks, motivation and boundaries.

NOTE 4: Appropriate estimation methods should be used.

NOTE 5: Examples of necessary resources are: people, infrastructure (such as tools, test equipment, communication mechanisms, etc.) and hardware/materials.

NOTE 6: Consider project risks (using MAN.5) and quality criteria (using SUP.1).

NOTE 7: Estimations and resources typically include engineering, management and supporting processes.

BP6: Confirm required skills, knowledge and experience. Identify the required skills, knowledge and experience for the project in line with the estimates and make sure the selected individuals and teams either have or acquire these in time.

NOTE 8: In the case of deviations from required skills and knowledge, training is typically provided.

BP7: Identify, monitor and adjust project interfaces and agreed commitments. Identify and agree interfaces of the project with other (sub) projects, organizational units and other affected stakeholders and monitor agreed commitments.

NOTE 9: Project interfaces relate to engineering, management and supporting processes.

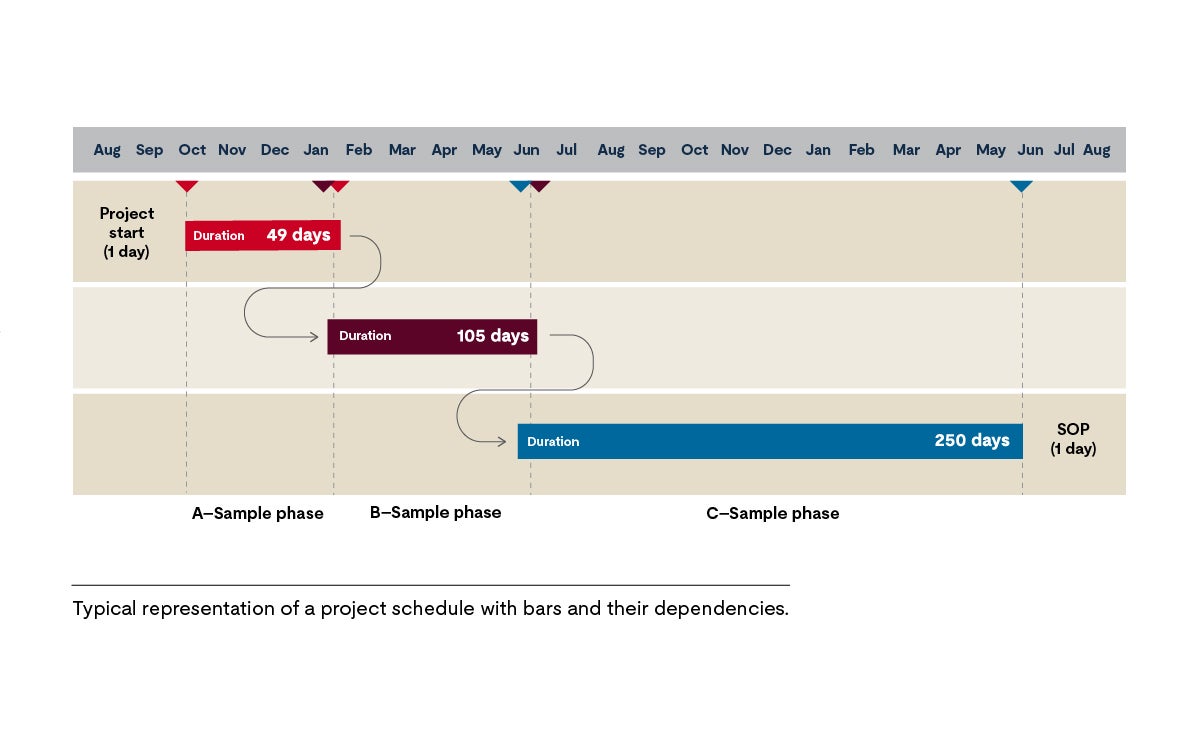

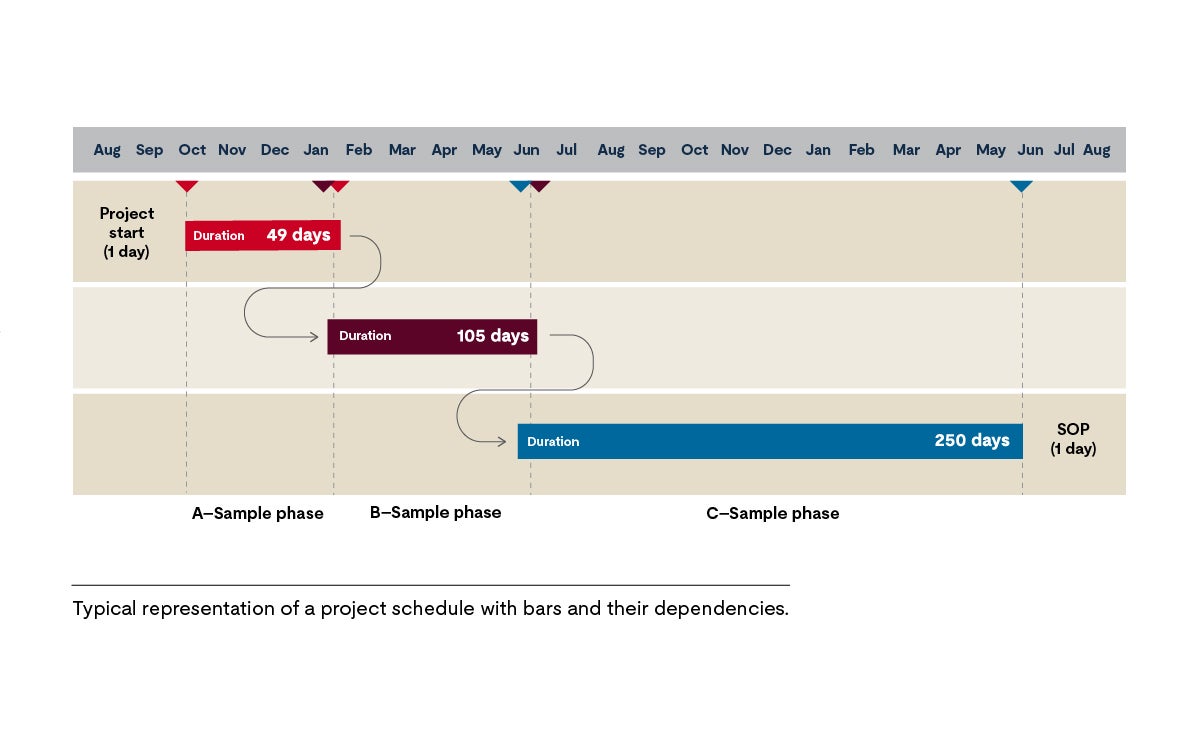

BP8: Define, monitor and adjust project schedule. Allocate resources to activities and schedule each activity of the whole project. The schedule has to be kept continuously updated during lifetime of the project.

NOTE 10: This relates to all engineering, management and supporting processes.

BP9: Check consistency. Verify that estimates, skills, activities, schedules, plans, interfaces and commitments for the project are consistent across affected parties.

BP10: Regularly review and report the status of the project and the fulfillment of activities against estimated effort and duration to all affected parties. Prevent recurrence of problems identified.

NOTE 11: Project reviews may be executed at regular intervals by the management. At the end of a project, a project review contributes to identifying, for example, best practices and lessons learned.

Output Work Products: Project plan, communication record, change request, review record, corrective action register, schedule, work breakdown structure, stakeholder groups list.

Advanced tutorial about Project Management

What is the benefit of Project Management?

Good project management enables timely detection and correction of deviations. Through appropriate communication, all relevant stakeholders are involved.

What is the content of the Configuration Management Process?

- The scope of the project is defined (BP1). This can be done by identifying boundaries of the project and its constraints. Also, it should cover the motivation.

- A project lifecycle model suitable for the scope of the project is defined (BP2), and consistency is provided to the customer processes (e.g., by mapping customer milestones to the model).

- Technical feasibility needs to be checked, but also whether the suggested timing plan makes sense, the budget is sufficient and whether the organization will have the resources required in the timeframe planned (BP3).

- Activities are derived from the WBS considering both the life cycle model and the effort estimations. Dependencies between activities are established. Progress monitoring and ongoing changes lead to many adjustments throughout the project (BP4).

- Effort and resource estimation (BP5) usually starts on the WBS level and is then broken down to the activity level when activities are being derived (see BP4).

- Resources include budget, people and infrastructure. It is expected that estimation methods are used. Estimations need to be monitored and adjusted throughout the project to ensure that they are still sufficient.

- The schedule is set up, monitored and maintained (BP8). This involves assigning people to activities.

- Required skills, knowledge and experience are identified (BP6) in parallel to BP4/5/8. Suitable people are acquired in time and/or it is assured that the people available meet the requirements (through training, mentoring, self-study, etc.). This needs to be in line with the estimates.

- The interfaces within and outside the project are determined. This involves mainly meetings and reporting. Commitments are determined, either in the plan, schedule or elsewhere. It is made sure that interfaces and commitments work as planned and necessary adjustments are made throughout the project (BP7).

- The various planning documents are checked for consistency across all parties involved and throughout the project (BP9).

- Project progress is regularly reviewed and reported to all relevant parties. This covers work progress, timing and effort consumed. Recurrence of problems needs to be prevented (BP10).

Typical representation of a project schedule with bars and their dependencies

Experiences, problems and hints:

- Work breakdown structures presented in assessments (if they exist) are often incomplete because most of the non-engineering topics are missing. The same is true for estimations.

- A lifecycle model consisting of three phases is not nearly sufficient and needs to be much more detailed, e.g., showing all delivery cycles, each of them with a partially or fully formed V model (even though the V-model may be the most popular approach Automotive SPICE allows for other models).

- The size of activities on the lowest abstraction level should be typically somewhere between one day and two weeks. If they are too small, the complexity is not manageable; if they are too large, risks increase.

- However, the level of granularity decreases for faraway activities (rolling wave planning). Detailed planning is less practical for work tasks the further out in the future that they occur. Instead, create and maintain detail tasks for the current release and maybe one or two more releases. Follow those detailed release plans with less granular tasks to the end of the project.

- Quite often, expert estimation is used. However, typical weaknesses with these are ballpark estimations (ten numbers for an entire project), incomprehensible methods, poor justifications and estimations completed in the beginning and never changed.

- Typically, inconsistencies arise between the work breakdown structure, the estimates, the schedules and the work capacity available (as shown in the schedule and in the staffing list) across all teams. This is extremely difficult because of the number of changes. Projects that manage to keep the work breakdown structure, the estimates, the schedules and the work assigned to activities in one common tool have a realistic chance to get this done.

- It is often overlooked how to address answering the most basic of questions for project management: Do we have enough resources to finish the work we are committed to complete by the next deadline? If this cannot be answered easily, then the planning system is insufficient.

Want to become an Automotive SPICE® expert?

If you’re serious about learning Automotive SPICE®, participate in one of our Automotive SPICE® Courses.

Read our related content

Automotive SPICE® Project Management (MAN.3) resource guide

Services for Automotive SPICE and Extensions