Jump directly to

- Introduction

- How to use this guide

- Identification of listed and certified products

- Identification of classified products

- Identification of verified products

- General characteristics

- Wire and cable marking tables 1, 2 and 3

- Explanations for column headings in marking tables

- Explanations of notes for marking tables

- Temperature (ºC) dry and temperature (ºC) wet

- Voltage (v)

- Outdoor use

- Sunlight resistance

- Cable tray use

- Oil resistance

- Gasoline resistance

- Direct burial

- Submersible pump use

- Other

- Appendix

Introduction

This guide is intended to assist code authorities, installers and contractors in determining the suitability of UL Certified, Listed, Classified and Verified wire and cable for use in a specific installation. Toward this goal, the guide:

- Clarifies the means used to identify UL Certified, Listed, Classified and Verified wire and cable. (See the sections titled “Identification of Listed Products,” “Identification of Classified Products” and “Identification of Verified Products.)

- Provides an explanation of the ratings and intended uses of UL Certified, Listed, Classified and Verified wire and cable. (See Appendix A for designations.)

- Focuses on the information contained in UL Certified, Listed, Classified and Verified wire and cable product markings (what the markings mean, where they may be located, etc.).

This guide does not address wire and cable evaluated only for suitability as factory-installed component wiring in other Listed equipment. Those products are Recognized by UL Solutions under the Component-Appliance Wiring Material (AWM) and Component-Nonshielded Cable categories and are not identified with a National Electric Code ® (NEC) wire Type designation.

In general, component wire or cable is not evaluated for field installation unless it is included as a part of a complete, Listed product or system. For example, data processing equipment Listed under the Information Technology Equipment Including Electrical Business Equipment (NWGQ) category will use external interconnect cables, such as AWM Style 2464, only if the AWM has been evaluated and described in the Listing for the particular piece of equipment. The limitations on the installation of the Listed end-use product or system also apply to the wiring. Some interconnect cables may have connectors assembled on one or both ends as a computer-interconnection assembly. When these assemblies use Recognized cable and are sent to a building site separately, instead of being supplied with the equipment, these cable assemblies may be identified as Listed Computer Interconnection Cable Assemblies (DVPJ). Similarly, for communication equipment, Listed Communication Cable Assemblies (DUNH) may be used. AWM ratings and conditions of acceptability are shown on a tag affixed to the reel or carton. Some ratings may appear on the surface of the wire or cable.

The UL Solutions label is required for Certified, Listed, Classified and Verified wire and cable products and can be applied in various manners. It can be applied to a coil, reel, flange or box.

The UL Mark appearing on the coil, reel, flange or box is the only means to identify wire/cable covered under UL Solutions certification and UL Solutions Follow-Up Services. Surface-printing the UL Solutions symbol or letters “UL” on the wire/cable is only a supplemental method of marking the product and should not be considered as evidence of UL Solutions coverage. UL Solutions’ guide information located in UL Product iQ® at productiq.UL.com indicates if the UL Solutions symbol or letters on the wire/cable itself is required or permitted. Engineering markings, which appear on the wire/cable, are only intended to provide information related to the product’s ratings or testing scope.

This guide should be particularly useful for those who:

- Have a working knowledge of the current edition of the National Electrical Code® (NEC) and how locally applicable electrical codes relate to the NEC.

- Are already familiar with the requirements of the electrical installation under consideration.

- Can identify the cable as a particular type.

This guide is intended to supplement the guide information for the appropriate wire and cable categories in the Product iQ database and the NEC. The UL Category Code for each wire and cable category is identified in Tables 1, 2 and 3 of this Marking Guide.

How to use this guide

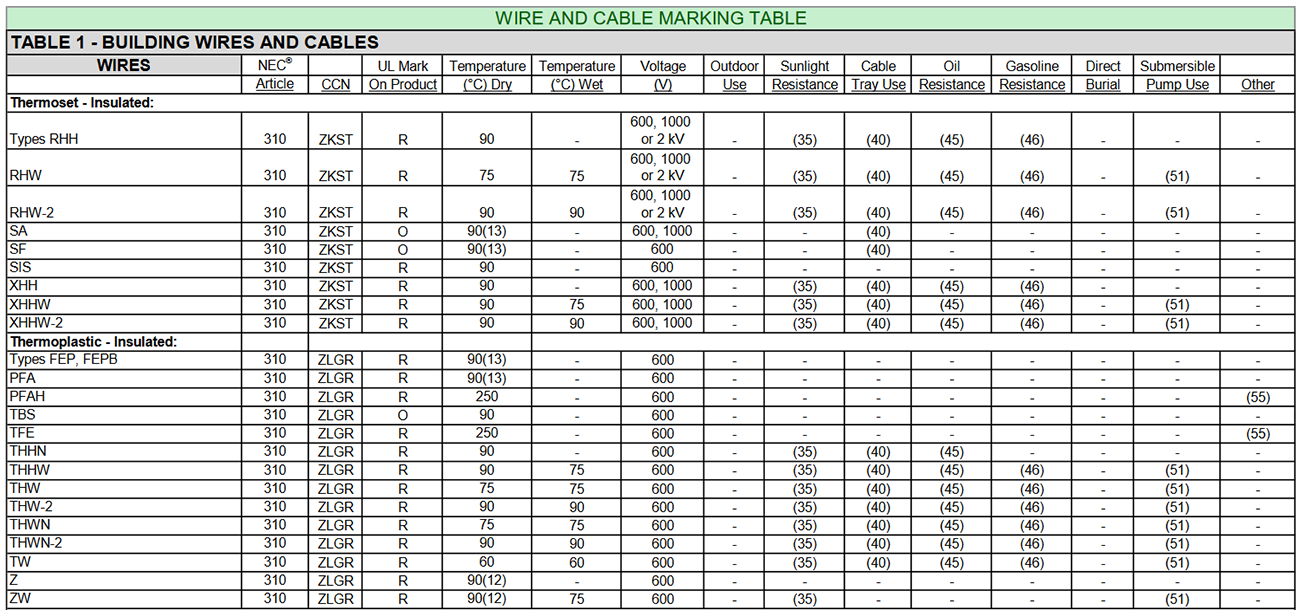

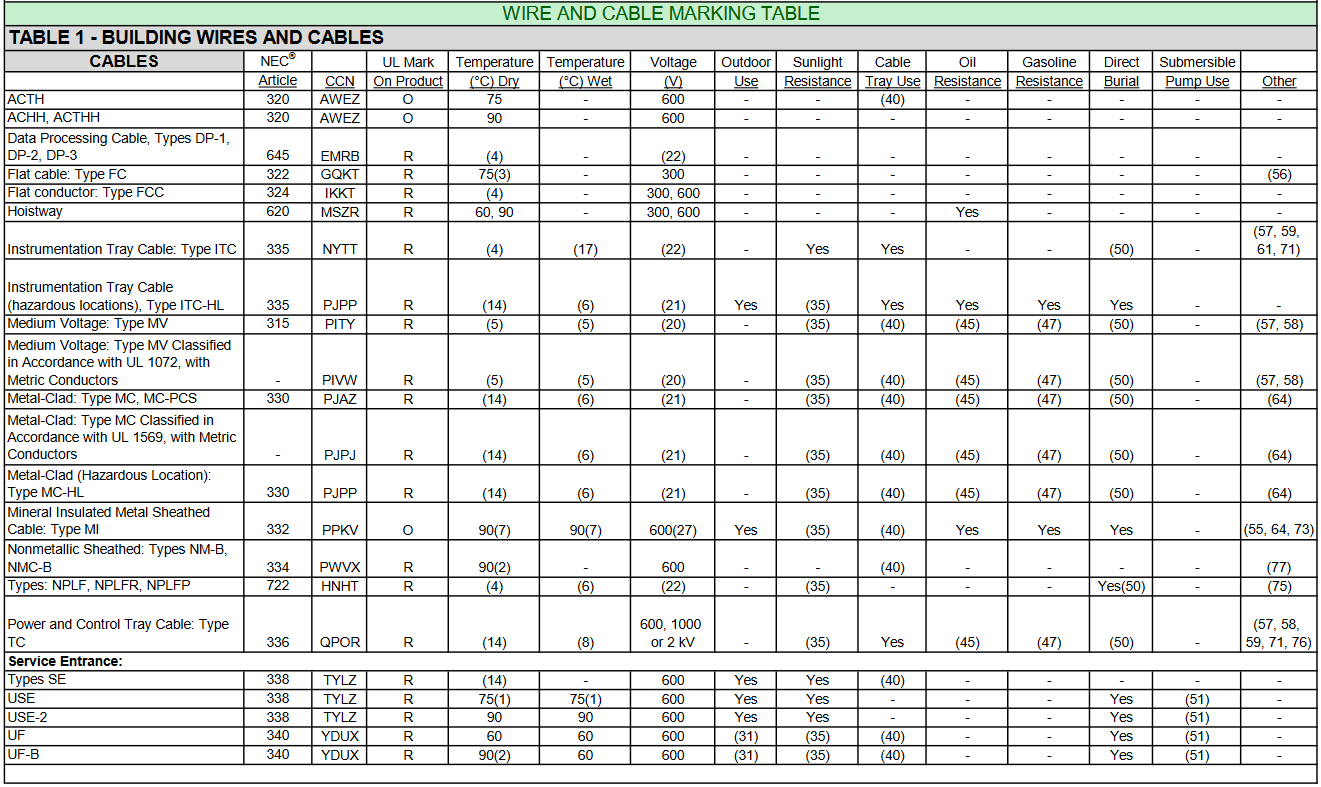

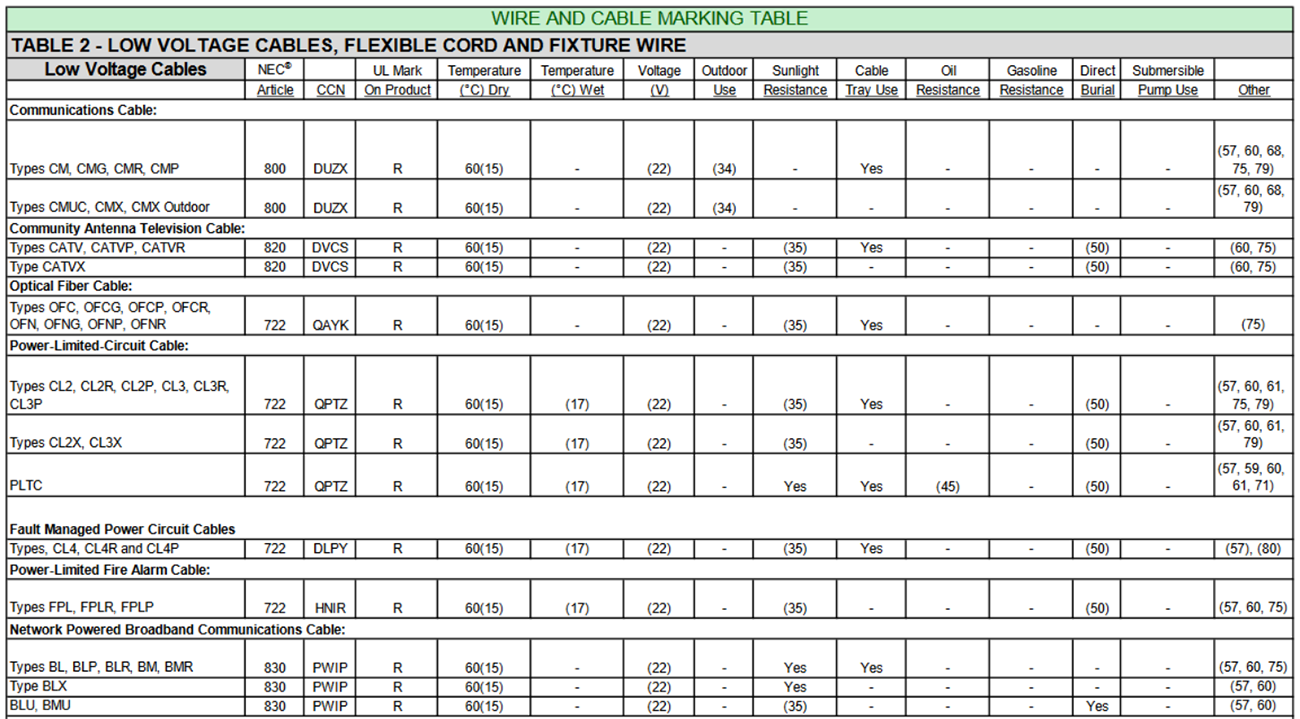

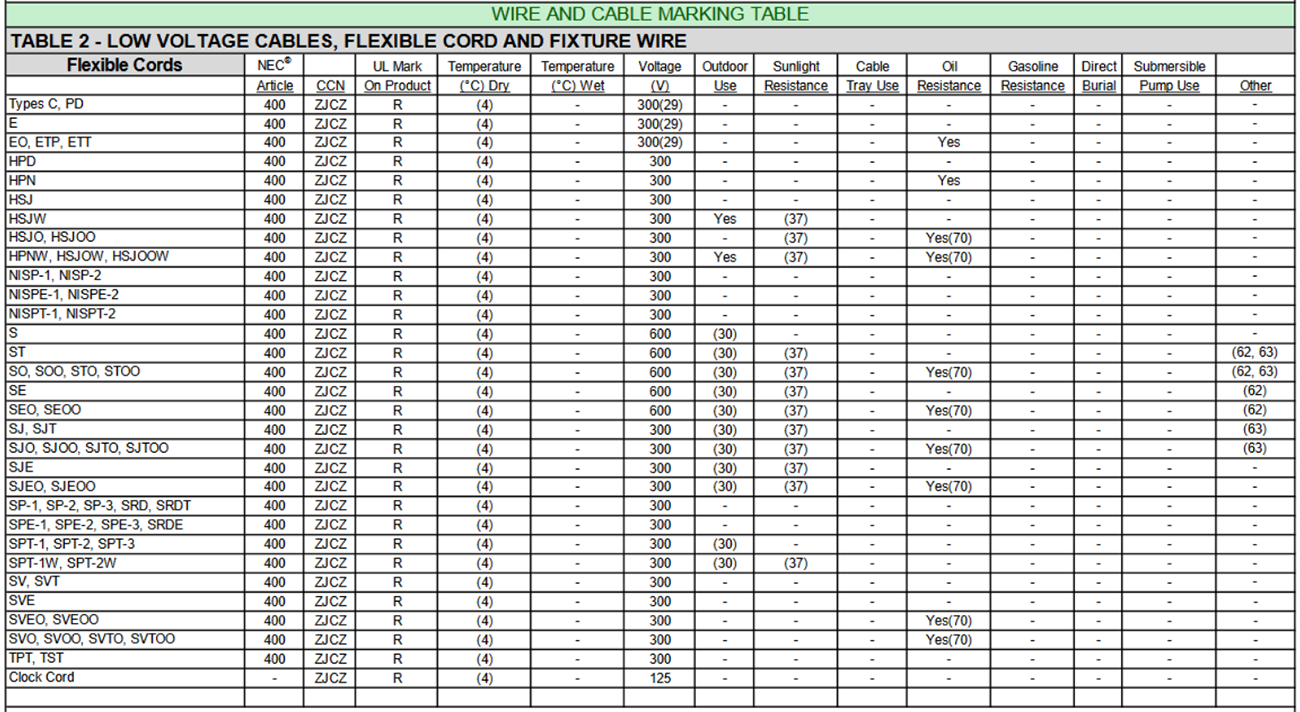

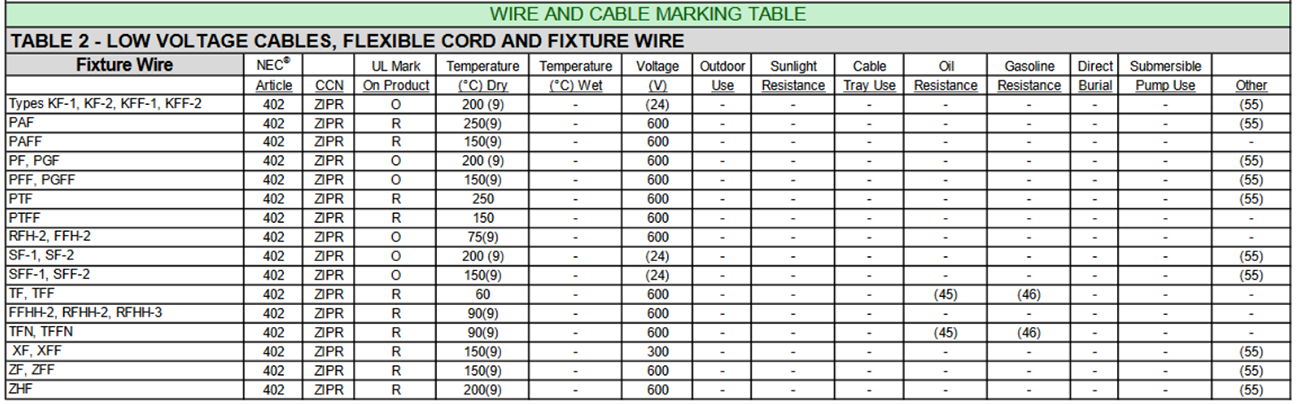

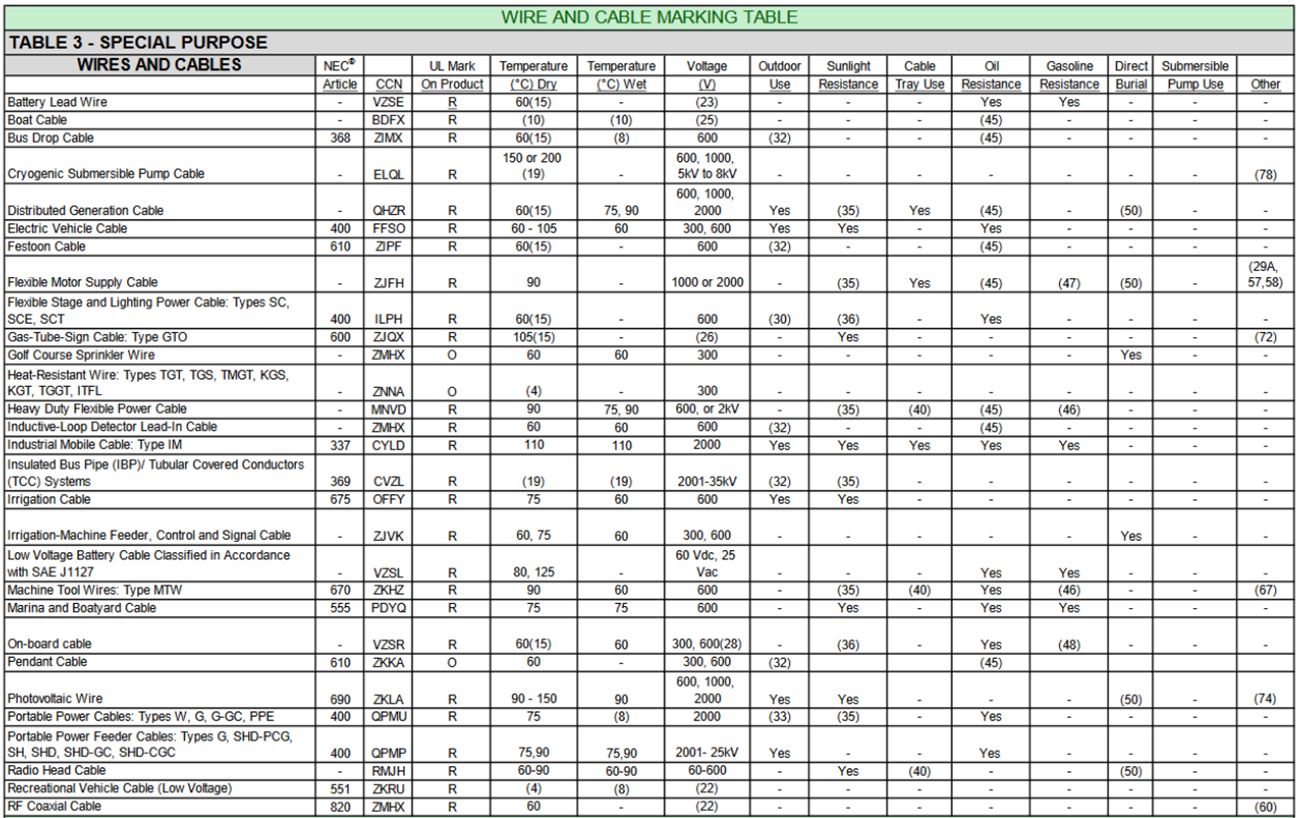

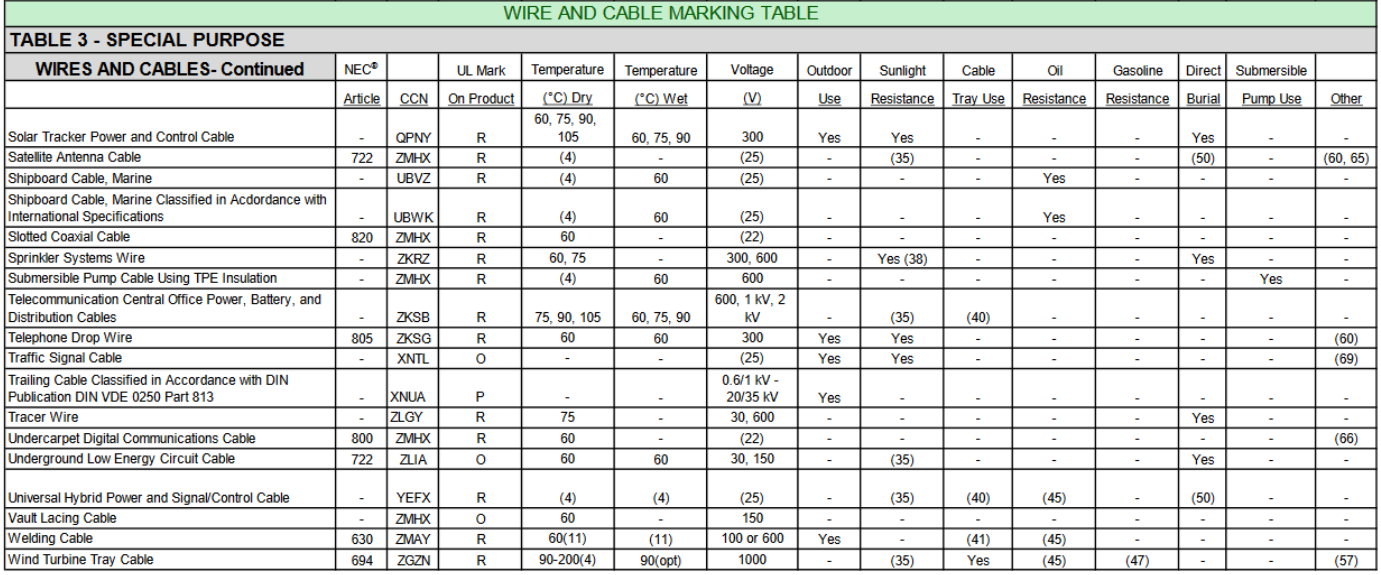

The wire and cable types covered in this guide have been divided into three tables as follows:

Table 1 — Building wires and cables, including some industrial cables

Table 2 — Low voltage c ables, flexible cords, and fixture wires

Table 3 — Special purpose w ire and cable

In each table, wire and cable types are identified by the name of the category under which they appear in the Product iQ database. Most wire and cable types have the same category designation in Product iQ as they do in the NEC.

Definitions of the column headings and codes used in each column are provided in the section titled “Explanations and Notes for Marking Tables.” Table entries consist of:

| Table entry | Indicates |

|---|---|

| Yes | The wire or cable is always evaluated for the use specified by the particular column. These uses are explained in the section titled “Explanations and Notes for Marking Tables.” |

| — (dash) | The wire or cable is not evaluated for the indicated use, either as a requirement or as an option. |

| Numbers | A specific rating. For example, 250 in the column headed by “Temperature (ºC) Dry” indicates a 250ºC temperature rating for dry locations. |

| Numbers in parentheses e.g., (3), (21) | Specific notes detailing a rating and/or associated marking. The explanations of the notes can be found in “Explanations and Notes for Marking Tables,” following the tables. |

Information on certification, listing and classification

Most codes and regulations require the certification of this equipment to applicable safety-related standards. They also may require this equipment to be certified to energy performance standards as well. Products that are certified to safety-related standards have been evaluated with regard to all reasonably foreseeable safety-related hazards, including fire, electrical shock and mechanical hazards. Such products are termed “UL Listed.” Products that are certified to a limited range of hazards, or for use under specific conditions are termed “UL Classified.” Alternatively, any of these products can be “UL Certified” and bear the UL Certification Mark.

It is important to distinguish the difference between “UL Listed” and “UL Classified” and the relation these terms have with the term “listed,” as used in various codes. The term “listed” in the codes generally indicates that the product is required to be evaluated in accordance with the appropriate standard(s) by an independent third-party certification organization such as UL Solutions. The term “listed” in the codes should not be confused with the term “UL Listed,” as explained previously. It is important to recognize that not all certification agencies make this distinction in their certification services.

Information on UL Marks

There are several types of UL Marks that can be found on wire and cable. General information about each of these Marks is provided in the following paragraphs. Each has its own specific meaning and significance. The only way to determine if a product has been certified by UL Solutions is to look for the UL Mark on the product itself.

The UL Mark on a product means that UL Solutions has tested and evaluated representative samples of that product and determined that they meet the requirements in the applicable standard(s). Under a variety of UL Solutions programs, certified products are periodically checked by UL Solutions at the manufacturing facility to determine that they continue to comply with the standard(s).

The UL Marks may only be used on, or in connection with, products certified by UL Solutions and under the terms of a written agreement between the manufacturer and UL Solutions.

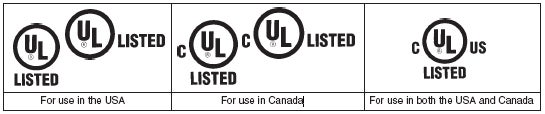

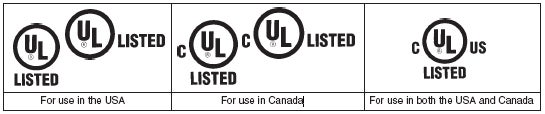

Identification of Listed products

The UL Mark may have various information around it, as authorized by UL Solutions.

The Listing Mark of UL Solutions on the attached tag, the reel or the smallest unit container in which the product is packaged, with or without the UL Solutions symbol on the product, is the only method provided by UL Solutions to identify these products manufactured under its Listing and Follow-Up Service. The Listing Mark for these products includes the UL Solutions symbol (as illustrated above) together with the word “LISTED,” a serial number and the product or category name.

A product bearing the UL Mark for Canada is Listed to Canadian Standards for that specific product. A product bearing the combined Canada/U.S. Mark is Listed to both UL (U.S.) Standards and Canadian Standards for that specific product.

For wire and cable products, the complete Listing Mark is located on a tag attached to the reel or smallest unit container. Two types of UL Solutions symbols — “UL” in a circle or “UL” in parentheses — may be found on the wire or cable itself. These UL Solutions symbols may also be preceded by the letter “C,” indicating certification only for Canada, or preceded by a “C” and followed by “US”, indicating certification for both the U.S. and Canada. The product markings are intended to provide information only, and the complete Listing Mark is the only proof that a particular unit of wire or cable is actually UL Listed.

To provide consistent control and marking, and to address potential counterfeiting issues, holographic labels are required on all Listed, Flexible Cords and Cables, Class 4 cable, Communications cable, Communications cable verified to UL Performance Category Program, Data transmission cable verified in accordance with national or international specifications, Community antenna television cables, Data processing cable, Non-power-limited fire-alarm cable, Power-limited fire alarm cable, Instrumentation tray cable, Network powered broadband communications cable, Optical fiber cable and Power-limited circuit cable.

Identification of UL Certified products

Launched in mid-2013, the enhanced UL Certification Mark can be used on both UL Listed and Classified products and is intended to make it easier for stakeholders to understand the scope of certifications by UL Solutions of a specific product. The enhanced Mark makes it possible to bundle multiple UL certifications for multiple geographies into a single Mark design. Today, this enhanced Mark is used for products certified to requirements of many geographies, including the U.S., Canada and Europe. This Mark utilizes a unique identifier to enable stakeholders to search the Product iQ database to quickly review detailed certification information.

All currently existing versions of the UL Listing and Classification Marks remain valid and should continue to be accepted as an indication of certification.

UL Solutions expects the transition to the enhanced Mark to happen over time, so you may not see it in the immediate future. For more information on this important development, please go to Marks and Label Hub. Access to the Marks and Label Hub is complimentary and open to all regulators, but registration is required to use it.

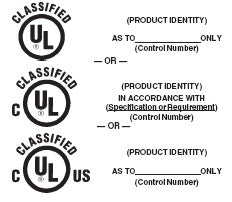

Identification of UL Classified products

With UL Solutions Classification service, UL Solutions determines that a manufacturer has demonstrated the ability to produce a product that complies with its requirements for the purpose of classification or evaluation regarding one or more of the following: (1) specific risks only, such as casualty, fire or shock; (2) performance under specified conditions; (3) regulatory codes; (4) other standards, including international and regional standards; or (5) other conditions UL Solutions may consider desirable. UL Solutions conducts UL Solutions Follow-Up Services as an audit of the means the manufacturer uses to determine continued compliance of the product with UL Solutions requirements. The UL Classified Mark may appear in various forms as authorized. The UL Classification includes: (1) the symbol of UL Solutions; (2) the word “CLASSIFIED”; (3) a product identity and a statement to indicate the extent of UL Solutions’ evaluation of the product such as “AS TO (nature of hazard) ONLY,” or a rating or classification as specified in the general information pertaining to the product category, or designation and title of standard published by other organization, or identification of specified product; and (4) a control number assigned by UL Solutions.

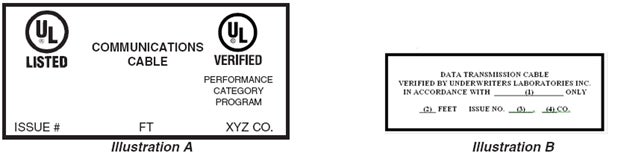

Identification of Verified products

The UL Verification Mark is used to identify products evaluated under UL Solutions performance Verification services . Some examples are products certified under the performance Verification program for cable, Proprietary Structured Cabling Program, ISO/IEC 11801 and ANSI/TIA 568.2-D.

The presence of this Mark provides confidence to end users, IT managers, LAN system designers and the regulatory community that products have been evaluated for transmission performance in order to meet the unique needs of the telecommunications industry community.

There are two formats to the UL Verification Mark (holographic label) that appear on products: Listing and Verification (as shown in Illustration A) and Verified-Only (as shown in Illustration B).

Listed cable also tested under the UL Solutions Performance Verification Program for cable in accordance to ANSI/TIA 568.2-D have the label marking “Listed Communications Cable” also “Verified to UL Solutions Performance Category Program,” on the tag, reel or smallest unit container, as shown in Illustration A. Cable Verified to another transmission performance specification (NEMA WC63, 63.1, 66, ISO 11801, etc.) have the label marking “Listed Communications, Cable” also “Verified in Accordance with [specification name and/or number]” on the tag, reel or smallest unit container. In addition, surface marking on these products would be as follows:

- For performance Category Cable : “Verified (UL Solutions) Category 3, 5, 5E, 6, 6A or 8 [including latest draft number if applicable].

- For performance Category Patch Cable: “Verified (UL Solutions) Category 3, 5, 5E, 6, 6A or 8 [including latest draft number if applicable] Patch Cable” for stranded conductor cables.

- For all other Performance Verified Cable: “Verified in Accordance with [specification name and/or number].”

Cabling products that are Verified Only (Non-UL Listed) will use the label as shown in Illustration B. The UL Solutions logo (UL in a circle with the two letters offset at a 30º angle from one another) is not permitted in the label artwork. The Verification Mark of Underwriters Laboratories on the attached tag, the reel or the smallest unit container in which the product is packaged is the only method provided by UL Solutions to identify products manufactured under this Verification and UL Solutions Follow-Up Services. The Verification Mark for these products includes the “VERIFIED by Underwriters Laboratories,” an issue or serial number, the product name “Data Transmission Cable,” and the specification name and/or number. In addition to the marking on the tag, reel or smallest unit container, cables that have been Verified by UL Solutions in accordance with the signal transmission characteristics, and have not been Listed by UL Solutions as Communications Cable are surface-marked with the statement “Verified by UL Solutions in accordance with [specification name(s) and/or number(s)] Only” in the surface print legend. The UL Solutions symbol [either the UL in a circle symbol or “(UL)”] is not used in place of the wording “UL Solutions ” in the statement.

General characteristics

Markings

The requirements for the exact text and location of the markings, and the method of identification, vary among the different types of wire and cable. Wherever possible, the product is surface marked with information necessary for proper installation. When surface marking is not possible — or for other considerations — a portion of the marking may be located on a marker tape, or on the tag, reel or the smallest unit container, as permitted by the requirements of each product category. Whenever possible, the rating or characteristic is plainly indicated. Other methods — for example, colored tracers under the jacket or insulation — may be used to identify a certain characteristic, such as temperature rating for some fixture wires. To completely determine the suitability of a particular wiring system, a review of the product, tag markings and carton markings may be necessary.

Some wire and cable may be marked with multiple Type designations. These products have been evaluated for uses of all Type designations marked.

All markings on or associated with wire and cable, as well as the Listing and guide information of the appropriate category, should be consulted to determine all ratings and limitations for proper installation in accordance with the requirements of the NEC.

UL Solutions evaluates wiring products with respect to the marked ratings and uses indicated by the Type designation associated with the UL Mark. Wiring products are not evaluated with respect to marked ratings and uses associated with other certification organizations.

Conductor material

Compact stranded copper conductors are identified by “compact” or “cmpct”; otherwise, wire and cable with bare or coated copper conductor material is not marked with stranding identification.

If the conductor material is either aluminum or copper-clad aluminum, the product, tag or carton markings (depending on the product category) identify the conductor material. These markings will appear as “AL,” “ALUMINUM,” “AL (CUCLAD),” “ALUMINUM (COPPER-CLAD),” “CU-CLAD AL” or “COPPER-CLAD ALUMINUM.”

For some wire and cable, other metals may be used as conductor material. The associated markings for that wire and cable are explained under the heading “OTHER.”

Flammability

UL Solutions investigates wiring products with respect to their intended locations and uses as permitted by the NEC. Flammability or resistance to spread or propagation of fire is one of the considerations that enters into the overall investigation of wire and cable. For instance, products that are inherently permitted by the NEC to be installed in cable trays or that are marked for such use are investigated for fire conditions that could exist in a cable tray.

Similarly, cables covered for use in accordance with Articles 722, 725, 760, 770, 800, 805, 820 and 830 of the NEC are investigated with respect to their application: plenum, riser, general use or limited residential use. Suffixes to the Type designation identify the use as defined in the appropriate NEC articles:

-P: Plenum

-R: Riser

-No Suffix, -G: General purpose

-X: Limited residential use

Some wire and cable may also have a suffix “ST1” (formally known as “-LS”), which means that the entire construction complies with the requirements for flame retardant, limited smoke wiring materials as evaluated per UL 1685, the Standard for Vertical-Tray Fire-Propagation and Smoke-Release Test for Electrical and Optical-Fiber Cables, or UL 2556, Wire and Cable Test Methods.

Environmentally friendly ratings

Low Smoke Halogen Free

Cables marked with “-LSHF” indicates that the cable compounds and components have been evaluated to UL 2885, the Outline of Investigation for Acid Gas, Acidity and Conductivity of Combusted Materials and Assessment of Halogens, and the complete cable utilizing these compounds and components has been evaluated to IEC 61034-2.

RoHS

Cables marked with “-RoHS” indicates that the cable nonmetallic compounds and components have been evaluated to UL 746R and metallic components have been evaluated to UL 1368, the Outline of Investigation for Restricted Use Substances in Metallic Components.

Acid Gas

Cables marked with “AG14” indicate that the cable compounds and components have been evaluated to UL 2556 for acid gas level not to exceed 14% by weight when calculated as HCl.

Wire and cable marking tables 1, 2 and 3

Explanations for column headings in marking table

The column headings of Tables 1, 2 and 3 identify:

Wire and cable category/type

Lists each wire, cable and flexible cord category as it appears in the Product iQ database. Generally, the category, type or both are on the product.

NEC article

Indicates the primary NEC article that references the category/type. The NEC article is typically not marked on the product.

(CCN)- UL category control number

Products are Listed or Classified by UL Solutions under an appropriate product category. A four-letter category code is the UL Solutions product category code designation. Each UL Solutions product category code provides a direct link to the guide information for the product category. The guide information includes the scope of the products covered, information relating to limitations or special conditions applying to the product, the requirements used for the investigation of the products, installation and use information, and information on product markings and the UL Mark to be used on the product. Guide information is available in the Product iQ database. This category code is not marked on the product.

UL Mark on product

Indicates whether the UL Mark (“UL” in a circle or parentheses) is required (R), optional (O) or prohibited (P) on the product. See the section titled “UL Listing Mark .”

Explanation of notes for marking tables

Temperature (°C) dry and temperature (°C) wet

These two columns indicate temperature rating for the wire and cable when used in dry locations or when exposed to water or moisture such as in wet and damp locations.

Numbers in parentheses indicate the following:

- Wire evaluated for use at 90°C dry and wet is marked with the suffix “-2” after the Type designation.

- Cable is to be used at the ampacity for 60°C conductors in accordance with NEC, Table 310.16.

- Cords evaluated for water resistance have a “W” in the Type designation, i.e., Type SJTW. The terms “water resistant” or “water resistant 60°C” may also be marked in addition to the “W” designation.

- The wire or cable has been investigated for the temperature rating marked on the product, tag, reel or smallest unit container.

- Types MV-90 and MV-105 are evaluated for use in wet or dry locations at 90°C and 105°C, respectively. Type MV- 90 DRY is only evaluated for use in dry locations at 90°C.

- Cable evaluated for wet-location use may be marked “WET-LOCATIONS CABLE” or “WET-LOCS CABLE.” Such marking is not required on the cable, refer to the marking on the tag, reel or carton.

- 250°C for special applications in locations where environmental conditions require operation at above 90°C temperature. Temperatures of fittings are limited to 85°C in dry locations and 60°C in wet locations.

- Wire or cable evaluated for wet-location use is marked “60°C WET” or “75°C WET or “90°C WET.”

- Temperature rating may be indicated on the product by colored marker threads located under either the insulation or the separator, as in the following table:

Table Rating (°C) Color RFH-2, FFH-2 75 Green TFN, TFFN, RFHH-2, RFHH-3 90 Red XF, XFF, SFF-1, SFF-2, PFF, PGFF, PAFF, PTFF, ZF, ZFF 150 Orange SF-1, SF-2, PF, PGF, ZHF, KF-1, KF-2, KFF-1, KFF-2 200 Black PAF, PTF 250 Two Black - The cable is marked with one of the following temperature ratings or codes; when no code is indicated, the product is marked with the rating.

Rating Code 60°C dry 60ºC wet BC-1W1 75°C dry 60ºC wet BC-2W1 75°C dry 75°C wet BC-2W2 80°C dry 60°C wet BC-3W1 80°C dry 75°C wet BC-3W2 90°C dry 60°C wet BC-4W1 90°C dry 75°C wet BC-4W2 90°C dry 90°C wet BC-4W3 105°C dry 60°C wet BC-5W1 105°C dry 75°C wet BC-5W2 105°C dry 90°C wet BC-5W3 105°C (dry only) – 125°C (dry only) – 200°C (dry only) – - Welding cable rated 600V is investigated for use in 75°C dry or wet locations.

- 90°C dry and damp location. 150°C dry locations for special applications in locations where environmental conditions require maximum conductor operating temperatures above 90°C.

- 200°C in dry locations for special applications.

- The temperature rating of the cable is the rating marked on the cable or implied by the conductor type in the cable.

- Indicates minimum temperature rating. Suitable for use at higher temperatures if marked on the cable or cord. The higher temperatures (above 60°C) only apply to dry applications.

- Note relocated to (29)

- Cable evaluated for wet location use is marked “wet” or “wet location.”

- Cable evaluated for wet location use is marked “90C Wet or Dry.”

- Note not used.

Voltage (V)

Indicates voltage rating. If the rating is not marked on the product, the wire or cable has been evaluated for the rating entered in the table. If marked higher than the rating in the table, it is rated as marked. Notes in the tables indicate the following:

- The voltage rating (kV) is one of the following, as marked: 2.4, 5, 8, 15, 25, 28 or 35.

- 600V or 2kV. Type MC cable containing Type MV conductors has the voltage rating of the conductors. Type MV cable in Type MC cable armor is surface or tape marked “Type MV Type MC” and it has a Type MV cable Listing Mark.

- Type designation indicates suitability for use in accordance with the appropriate NEC article, with respect to voltage and power limitations.

- The voltage rating (dc) is one of the following, as marked: 30, 48, 60, 90 or 150.

- Rating is indicated by number in the Type designations as follows:

Suffix Rating (V) -1 300 -2 600 - The wire or cable may be evaluated for various voltage ratings. The rating is marked on the product, a tag attached to the reel or smallest unit container.

- Voltage rating is indicated on the product by a suffix after the Type designation as follows:

Suffix Rating (kV) -5 5 -10 10 -15 15 - Some mineral-insulated cable may be rated 300V for use in Class 1 remote control and signaling circuits not exceeding 300V.

- Rated ac or dc

-

- May be rated 600 volts when employing minimum 45-mil insulation.

- A – For 1000-volt-rated cables that are not surface marked with a type designation, the insulated conductors shall meet all performance requirements for conductors rated 600 volts with an increased dielectric withstand test. The conductors shall not be surface printed with any type letter designation. For 1000-volt-rated cables that are marked with the NEC conductor type, the insulated conductors meet the performance for conductors rated 1000V.

Outdoor use

- A product evaluated for outdoor use has a “W” in its Type designation, e.g. “SJTW.” For a cord evaluated and marked for recreational vehicle or mobile home use, outdoor use always applies and the marking “W” is optional.

- Type UF and UF-B cables evaluated for installation above ground are marked “SUNLIGHT RESISTANT.”

- Cable evaluated for outdoor use is marked “outdoor” or “outdoor use.”

- Cable evaluated for outdoor use is marked “SUNLIGHT RESISTANT” or “SUN. RES.” plus “60°C WET,” “75°C WET” or “90°C WET.”

- Type CMX cable marked “Outdoor” is suitable for installation outdoors on dwellings.

Sunlight resistance

“Yes” indicates that the outer nonmetallic covering of the product has been evaluated for direct exposure to ultraviolet (UV) radiation from the sun. This coverage is not generally marked on the product. Cables with an overall metallic covering are always considered suitable for exposure to sunlight. The use limitations and associated markings are specified in the tables by the following:

- A product evaluated for sunlight resistance is marked “SUNLIGHT RESISTANT,” “SUN. RES.” or “SR.”

- A product evaluated for sunlight resistance is marked “SUNLIGHT RESISTANT,” “SUN. RES.” or “W.”

- Cords with the ‘W’ suffix are suitable for use in wet locations and are sunlight resistant.

- Cable with an overall jacket may be marked “sunlight resistant.”

- Note not used.

Cable tray use

“Yes” indicates that the cable has been evaluated for use in cable trays in accordance with NEC Articles 310, 318 and other applicable articles. Generally, this coverage is not marked on the product. Notes in the tables indicate the following:

- When evaluated for use in cable trays, the product is marked “for cable tray use,” “for CT use” or “for use in cable trays.”

- For trays dedicated to welding cable only, per NEC Section 630.42. May be marked on the product.

(42), (43), (44) Notes not used.

Oil resistance

“Yes” indicates that the product has been investigated for use in locations exposed to oil at a temperature of 60°C or lower. Generally, this coverage is not marked on the product. If the product has been investigated for oil resistance at higher than 60°C temperatures, it is rated as marked.

- A product evaluated for 60°C oil resistance is marked “OIL RESISTANT I,” “OIL RES I,” “OIL RESISTANT” or “PRI.” A product evaluated for 75°C oil resistance is marked “OIL RESISTANT II,” “OIL RES II” or “PRII.”

Gasoline resistance

“Yes” indicates that the product has been evaluated for use in locations exposed to liquid gasoline, gasoline vapors and vapors from similar light petroleum solvents. Generally, this coverage is not marked on the product. Notes in the tables indicate the following:

- A product evaluated for 60°C oil resistance and for gasoline resistance is marked “GASOLINE AND OIL RESISTANT I” or “GR1.” Similarly, for 75°C oil and for gasoline resistance, the product is marked “GASOLINE AND OIL RESISTANT II” or “GR2.”

- When evaluated for gasoline resistance only, the insulated conductors are marked “GASOLINE RESISTANT.” If this marking appears on the outer covering of the cable, “GASOLINE RESISTANT” is followed by “CDRS,” “CONDS” or “CONDUCTORS.”

- A product marked with the suffix “G” has been evaluated for gasoline resistance.

- Note not used.

Direct burial

“Yes” indicates that the wire or cable has been evaluated for direct burial in the earth. Generally, this is not marked on the product. Notes in the tables indicate the following:

- When evaluated for direct burial use, the product is marked “FOR DIRECT BURIAL,” “DIRECT BURIAL,” “DIR BUR” or “DIR BURIAL.”

Submersible pump use

“Yes” indicates that the wire or cable has been evaluated for use in wiring of pumps and/or submersible pumps. Product name identifies the use. Notes in the tables indicate the following:

- When evaluated, the product is marked “PUMP CABLE” or “SUBMERSIBLE PUMP CABLE.”

(52), (53), (54) Notes not used.

Other

Uses, exposures and constructional features not otherwise covered in the tables are referenced in this column through the following notes. If not otherwise specified, the product has not been evaluated for any other condition unless marked on the product.

- Nickel or nickel-based alloy may be used with the product. Marking not required.

- Product is marked with the ampacity: “____ amp” or “____ A.”

- Optical Fibers. When these are present, the product is marked “Contains optical-fiber member(s)” or “OF” after the wire or cable Type designation.

- Gas/Vapor Blocked. When evaluated for gas/vapor blocking, the product is marked with “Gas/Vapor Blocked,” the minimum length required to attain the blocking, and the designation of the hazardous location for which the wire or cable is intended, such as “Class ____, Group ____.”

- The overall jacket on Types ITC, TC and PLTC is a “gas/vapor tight continuous sheath,” as indicated in Sections 501.15(D) and 501.15(E) of the NEC.

- Copper-clad steel conductor may be used with product. Copper clad aluminum may be used as the center conductor in a coaxial construction. Marking not required.

- Each pair of thermocouple-extension wires is marked with the nominal AWG size and one of three designations — “THCPLEXTN,” “For thermocouple-extension use only” or “Thermocouple-extension wire only,” — plus identification(s) from either of the following columns for the combination(s) of thermocouple-extension conductor metals used:

Only cables containing thermocouple-extension wire may have the markings on the cable instead of having each pair marked.Type Designation Combination of Metals JX Iron/Constantan KX Chromel/Alumel TX Copper/Constantan EX Chromel/Constantan SX, RX Copper/Alloy BX Copper/Copper NX Nickel-Chromium-Silicon/Nickel-Silicon-Magnesium GX Tungsten/Tungsten-26% Rhenium CX Tungsten-5% Rhenium/Tungsten-25% Rhenium DX Tungsten-3% Rhenium/Tungsten-25% Rhenium - Recreational Vehicle or Mobile Home Use. When evaluated for this use, the product is marked “For Mobile Home or Recreational Vehicle Use: _____ Amperes.”

- Low Leakage Current Rating. When evaluated for use as low leakage-current cord in a cord set or power-supply cord for earth-grounded, direct-patient, contact medical and dental equipment, the cable is marked “Max leakage/10 ft. at _____ V: _____ μA to green and _____ μA thru jacket.”

- Various conductor materials may be used. The metal type is marked on the tag attached to the reel or smallest unit container. In addition, “–PCS” may be marked on a MC cable to designate both power and/or lighting conductors and signal and/or control conductors intended for use in Class 2 or 3 circuits.

- Insulated conductors evaluated for a 600V rating are marked “Power Leg” on the insulation surface.

- Conductive Thermoplastic Shield or Jacket. Jacket or thermoplastic shield is conductive when the product is marked “Conductive PVC shield” or “Black material is conductive.”

- Flexing and Constant-Flexing Services. When evaluated for flexing services, the product is marked “Flexing” or “Class K.” When evaluated for constant-flexing services, the product is marked “Constant flexing,” “Class M” or “Class K.”

- Listed cables that are additionally marked “Verified UL Category 3, 5, 5E, 6, 6A or 8” comply with the UL Data Transmission Performance Category Marking Program. “CAT” may be substituted for “Category.” Listed cables that are additionally marked “Verified in Accordance With (Specification: Name and/or number)” comply with the requirements of a referenced transmission performance specification. For example, “Verified (UL) Category 6 or 7 NEMA WC-66.” Effective January 31, 2012, cables are evaluated in accordance with ANSI/TIA-568.2-D, “Balanced Twisted-Pair Telecommunications Cabling and Components Standards and Category 5 cables can no longer reference the ANSI/TIA-568.2-D Standard. Category 5 cables intended to bear a UL Verification Mark (label) and Verification surface markings can only be Verified under the “UL Performance Category Program”. Any surface print reference to TIA/EIA-568B or ANSI/TIA-568.2-D is prohibited.

- Classified in accordance with International Municipal Signal Association, Inc. (IMSA) specifications. Intended for use in underground conduit or as an aerial cable only. Not evaluated for use as a substitute for cables or wiring systems covered in the NEC.

- “OO” indicates oil resistant insulation and jacket. “O” indicates oil resistant jacket only.

- Cable suitable for use as described in NEC Sections 335.4(5), 336.10(7), 725.154(D)(1), or is surface marked with the suffix “– ER” (formerly “Open Wiring”) directly following the Type letters.

- Cables marked “Integral Sleeve” have been evaluated for equivalence to a GTO cable with a sleeve installed over it as required in some electric signs.

- MI cables with outer nonmetallic jackets are:

- Not suitable for use in ducts, plenums, or other spaces used for environmental air and are so marked.

- Marked “not suitable for us on or in buildings” if they have not been investigated for flame retardance. Such cables are sunlight resistant.

- Marked for cable tray use if they comply with the applicable flame test. These cables may be marked for sunlight resistance if applicable.

- Suitable for use with or without a raceway.

- Note not used.

- Cable suitable for use when pulled thru joists if surface marked with the suffix “-JP’.

- Type NM cable may be suffixed with “–PCS” designate both power and/or lighting conductors and signal and/or control conductors intended for use in Class 2 or 3 circuits.

- Fluid Compatibility liquid- when evaluated for use with fluids such as Liquified petroleum gas, Natural Fuel Gases including methane, propylene, liquid nitrogen, acetylene, hydrogen, natural gas and other liquified flammable gasses. Marked “–RB” " when evaluated to the repeated u-bend at cold temperature test described in UL 1385, the Outline of Investigation for Cryogenic Submersible Pump Cable.

- Cables that comply with the cable heating test may be marked with the suffix “LP (XX)” where “XX” shall be 0.5A, 0.6A, 0.7A, 0.8A, 0.9A or 1.0A to designate the current rating of each conductor in the cable. If so marked, the suffix “LP” shall be added immediately after the cable designation. This marking is optional.

- Cables employing 18 AWG and smaller conductors that comply with the cable heating test shall be marked with the suffix “FMP (XXA)” where “XX” is the current rating of each conductor in the cable. If so marked, the suffix “FMP” shall be added immediately after the cable designation.

Appendix

Suitable for use with or without a raceway

Wire, cable and cord designations

In general, the letter designations assigned to wire, flexible cord and cable in the NEC, for identification purposes, are established according to a coding system that provides information on intended use, insulation type and insulation temperature rating. This coding system, to which there are exceptions, does not cover all NEC designations. The coding system is as follows:

Conductors for general wiring

| B | Braid |

| FEP | Fluorinated ethylene propylene insulation |

| H | 75°C (Note: Lack of “H” indicates 60°C) |

| HH | 90°C |

| N | Nylon jacket |

| PFA | Perfluoroalkoxy insulation |

| R | Thermoset insulation |

| S | Silicone (Thermoset ) insulation |

| T | As first letter – Thermoplastic insulation |

| TFE | Polytetrafluoroethylene |

| U | Underground use |

| W | Moisture resistant |

| X | Cross-linked polymer insulation |

| Z | Modified ethylene tetrafluoroethylene insulation |

| Examples: | RHW –Thermoset insulation, 75°C, Moisture resistant |

| THHN –Thermoplastic insulation, 90°C dry, nylon jacket |

Flexible cord and cable

| E | As first letter — Elevator cable |

| E | After first letter — Thermoplastic elastomer insulation and jacket |

| EV | Electric Vehicle Cable |

| H | Heater cord |

| NI | “Non-Integral ,” used for parallel cords such as Type NISPT-1 to denote insulated conductors and jacket are separate |

| O | Oil resistant. Single “O” means jacket only is oil resistant; double “O” means jacket and conductor insulation are oil resistant |

| S | Extra hard usage Flexible Cord |

| SJ | Hard usage Flexible Cord |

| SV | Not hard usage Flexible Cord |

| T | As the first letter — Tinsel cord. Single flattened 27 AWG conductor wound around insulating core, for very low current, highly flexible application |

| T | After the first letter — Thermoplastic insulation and jacket |

| XTW | Parallel cord for decorative lighting strings |

| CXTW | Twisted pair cord or single conductor for decorative lighting strings |

| W | As the last letter — Suitable for use in wet locations and sunlight resistant |

| W | As the only letter — Portable Power Cable |

| Examples: | SJTO — Hard usage, thermoplastic, oil resistant jacket |

| -1, -2, -3 | SPT-2 — Parallel Cord, thermoplastic |

Fixture Wire

| F | Fixture wire, standard stranding |

| FF | Fixture wire, flexible stranding |

| G | Glass braid |

| H | 75°C insulation |

| HH | 90°C insulation |

| K | Aromatic polyimide tape insulation |

| N | Nylon jacket |

| P | Fluorinated ethylene propylene insulation |

| R | Thermoset insulation |

| S | Silicone (Thermoset ) insulation |

| T | Thermoplastic insulation |

| X | Cross-linked synthetic polymer insulation |

| Z | Modified tetrafluoroethylene insulation |

| -1, 2, 3 | Insulation thickness, thinnest to thickest for some types. Actual insulation thickness varies, with insulation types and AWG size. |

| Examples: | SF-1 — Silicone rubber fixture wire |

| TFF — Thermoplastic, flexible stranded fixture wire |