Hazardous Locations Explosion Protection Services

Hazardous locations and explosion-protected equipment intended for installation in the European Union must comply with the ATEX Directive 2014/34/EU, which replaced the former ATEX Directive 94/9/EC.

UL is one of the top issuers of global ATEX and IECEx certifications. This supports acceptance of your UL-issued certificates, test reports and quality audits for local country marks around the globe. The UL brand is highly recognized and accepted by certifiers, installers and regulators in local, regional or international markets. Leverage our global brand acceptance and trust to add value to your innovations.

Hazardous locations and explosion-protected equipment intended for installation in the European Union must comply with the ATEX Directive 2014/34/EU, replaced the former ATEX Directive 94/9/EC. The directive ensures the free movement of goods throughout the European Union (EU) by harmonizing compliance procedures. We are an accredited Notified Body and Ex Testing Laboratory for electrical and nonelectrical equipment based on the EN 60079, EN 80079 and EN 13463 series of harmonized standards. We can also help with functional safety requests. Learn about ATEX certification and area classification, including applicable HazLoc Directives, markings, and the difference between Groups and Categories.

Certification process services include:

Organizations in the EU must follow directives to help protect employees from explosion risk in areas with an explosive atmosphere.

There are two ATEX Directives (one for the manufacturer and one for the user of the equipment):

The Directive 2014/34/EU became effective on April 20, 2016 and it affects manufacturers for the following:

Links to resources:

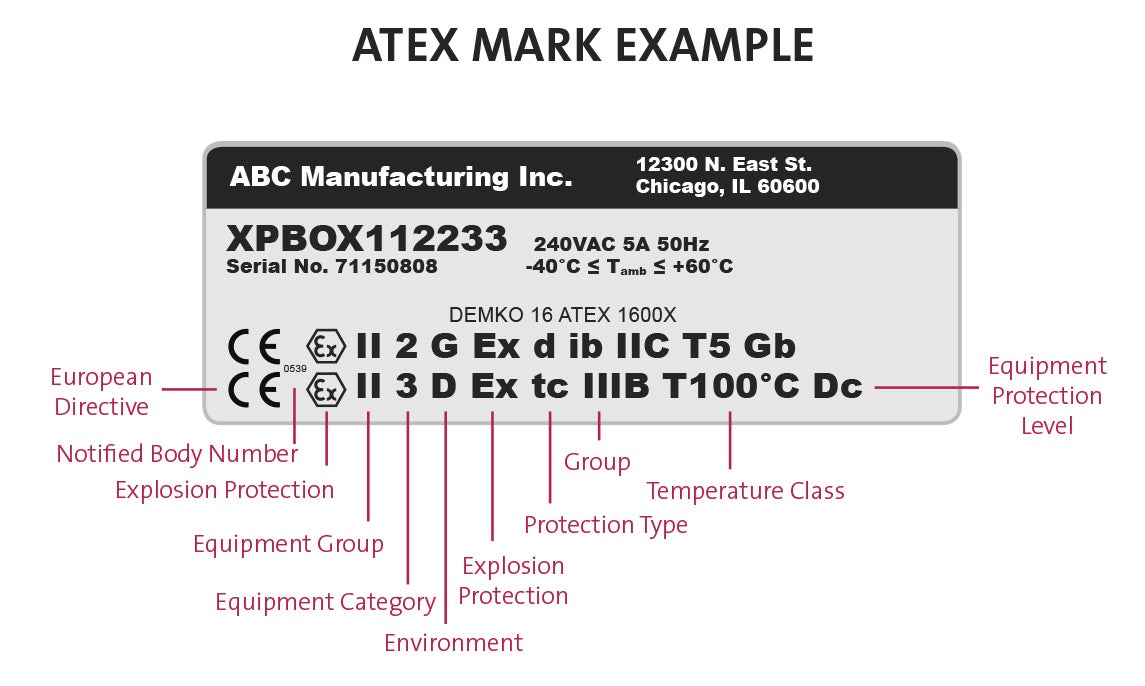

Hazardous areas are divided into Groups and Categories and further subdivided into Zones, Groups, Protection Types, and Equipment Protection Levels (EPLs).

Sample Marking:

Groups and Categories are defined in the ATEX Directive 2014/34/EU, as follows:

Zones are defined in the ATEX Workplace Directive 1999/92/EC, as follows:

Mines Susceptible to Firedamp

For your convenience, UL has recently added ATEX Certificates to our online certification directory. This database enables fast, easy and reliable access for both you and your customers.

Thanks for your interest in UL's products and services. Let's collect some information so we can connect you with the right person.